CO2 Incubator

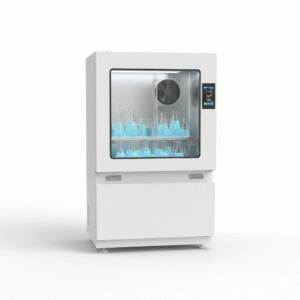

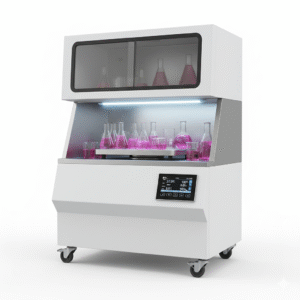

A forced-air drying oven uses a fan to circulate heated air throughout the chamber, which provides a uniform temperature and faster drying times compared to gravity convection ovens. It is used for drying, sterilizing, and heat-treating various materials in laboratories, industrial and mining enterprises, and scientific research units.

Key features of a forced-air drying oven typically include:

- Forced air circulation: A fan ensures even heat distribution and quick heating.

- Temperature control: Most models feature a microprocessor or PID controller with a digital display for accurate and reliable temperature settings.

- Inner chamber: The interior is often made of stainless steel for durability and easy cleaning.

- Viewing window: A double-layer glass door allows for observation of samples without disturbing the internal environment.

- Safety features: Common safety features include over-temperature protection, leakage protection, and alarms.

The oven is commonly used across a variety of fields, including:

- Research and development: Drying samples for analysis, sterilizing equipment, and curing materials.

- Pharmaceutical and chemical industries: Drying and sterilizing glassware, and conducting stability testing.

- Food industry: Baking, drying, and dehydrating food products.

- Electronics industry: Drying components and curing coatings.

Category Uncategorized

Description

This is a laboratory oven, specifically a forced-air drying oven.

A forced-air drying oven uses a fan to circulate heated air throughout the chamber, which provides a uniform temperature and faster drying times compared to gravity convection ovens. It is used for drying, sterilizing, and heat-treating various materials in laboratories, industrial and mining enterprises, and scientific research units.

Key features of a forced-air drying oven typically include:

- Forced air circulation: A fan ensures even heat distribution and quick heating.

- Temperature control: Most models feature a microprocessor or PID controller with a digital display for accurate and reliable temperature settings.

- Inner chamber: The interior is often made of stainless steel for durability and easy cleaning.

- Viewing window: A double-layer glass door allows for observation of samples without disturbing the internal environment.

- Safety features: Common safety features include over-temperature protection, leakage protection, and alarms.

The oven is commonly used across a variety of fields, including:

- Research and development: Drying samples for analysis, sterilizing equipment, and curing materials.

- Pharmaceutical and chemical industries: Drying and sterilizing glassware, and conducting stability testing.

- Food industry: Baking, drying, and dehydrating food products.

- Electronics industry: Drying components and curing coatings.