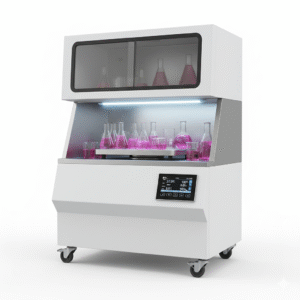

Lab Rotary Evaporator

The device shown in the image is a rotary evaporator, also commonly known as a rotovap or rotavapor. It is a piece of laboratory equipment used for the efficient and gentle removal of solvents from a sample by evaporation.

Principle of Operation

A rotary evaporator works by combining three key principles to accelerate evaporation and protect the sample:

- Reduced Pressure: A vacuum pump lowers the pressure inside the system, which significantly reduces the boiling point of the solvent. This allows the solvent to evaporate at a much lower temperature than it would at atmospheric pressure.

- Heat: A heated fluid bath warms the round-bottom flask, providing the thermal energy needed for the solvent to evaporate.

- Rotation: The flask is rotated by a motor, which spreads the liquid sample into a thin film on the inner surface of the flask. This increases the surface area for evaporation, making the process faster and more uniform while also preventing “bumping” or violent boiling.

The evaporated solvent vapor then travels to a condenser, where it is cooled and returned to a liquid state, dripping into a separate collection flask. The concentrated non-volatile compound is left behind in the original round-bottom flask.

Common Applications

Rotary evaporators are widely used in various fields, including:

- Pharmaceutical and Chemical Industries: For concentrating active pharmaceutical ingredients (APIs), purifying intermediates, and recovering solvents for reuse.

- Natural Product Extraction: To gently extract essential oils and other bioactive compounds from plant materials for cosmetics, food, and fragrances.

- Academic and Research Laboratories: For general solvent removal and sample preparation.

- Molecular Gastronomy: To create unique flavors and aromas by distilling ingredients at low temperatures for use in cocktails and other culinary creations.

Category Uncategorized

Description

The device shown in the image is a rotary evaporator, also commonly known as a rotovap or rotavapor. It is a piece of laboratory equipment used for the efficient and gentle removal of solvents from a sample by evaporation.

Principle of Operation

A rotary evaporator works by combining three key principles to accelerate evaporation and protect the sample:

- Reduced Pressure: A vacuum pump lowers the pressure inside the system, which significantly reduces the boiling point of the solvent. This allows the solvent to evaporate at a much lower temperature than it would at atmospheric pressure.

- Heat: A heated fluid bath warms the round-bottom flask, providing the thermal energy needed for the solvent to evaporate.

- Rotation: The flask is rotated by a motor, which spreads the liquid sample into a thin film on the inner surface of the flask. This increases the surface area for evaporation, making the process faster and more uniform while also preventing “bumping” or violent boiling.

The evaporated solvent vapor then travels to a condenser, where it is cooled and returned to a liquid state, dripping into a separate collection flask. The concentrated non-volatile compound is left behind in the original round-bottom flask.

Common Applications

Rotary evaporators are widely used in various fields, including:

- Pharmaceutical and Chemical Industries: For concentrating active pharmaceutical ingredients (APIs), purifying intermediates, and recovering solvents for reuse.

- Natural Product Extraction: To gently extract essential oils and other bioactive compounds from plant materials for cosmetics, food, and fragrances.

- Academic and Research Laboratories: For general solvent removal and sample preparation.

- Molecular Gastronomy: To create unique flavors and aromas by distilling ingredients at low temperatures for use in cocktails and other culinary creations.