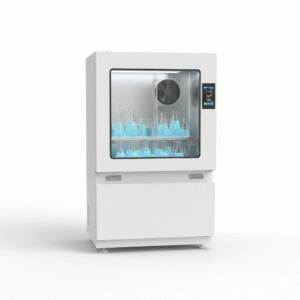

Convection Oven

is a forced air convection drying oven, also known as a mechanical convection oven or hot air oven. This type of laboratory equipment is used for a variety of tasks that require uniform and controlled heat, such as drying, sterilizing, curing, and heat treatment.

How a Forced Air Convection Oven Works

A forced air oven utilizes an internal fan to circulate heated air throughout its chamber. This forced air movement ensures a consistent and uniform temperature distribution, which is a key advantage over gravity convection ovens that rely on the natural rising of hot air. The continuous circulation of hot air prevents the formation of cold spots, resulting in faster heating and drying times.

Common Applications

Forced air convection drying ovens are used in a variety of fields, including:

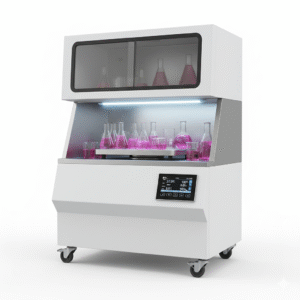

Laboratories and Pharmaceuticals: For drying glassware, sterilizing instruments, and preparing samples. They are crucial for maintaining sterility and ensuring compliance with standards.

Food Processing: Used for dehydrating fruits, vegetables, herbs, and meats to extend shelf life and preserve flavor and nutrients.

Chemical and Material Science: Used to dry powders, granules, and other moisture-sensitive compounds, as well as for curing resins and annealing metals.

Electronics: Used for drying and curing electronic components.

Key Features

These ovens typically have several key features that contribute to their effectiveness and safety:

Temperature Range: Most models operate from about 10-15°C above ambient temperature up to 250°C or 300°C, with some industrial models reaching even higher temperatures.

Digital Control: Advanced models feature digital PID controllers for superior temperature accuracy and programmable cycles.

Construction: The inner chamber is often made of stainless steel for corrosion resistance and easy cleaning, while the outer body is typically powder-coated steel.

Safety: Essential safety features include overheat protection and door interlocks to ensure safe operation.

Description

forced air convection drying oven

is a forced air convection drying oven, also known as a mechanical convection oven or hot air oven. This type of laboratory equipment is used for a variety of tasks that require uniform and controlled heat, such as drying, sterilizing, curing, and heat treatment.

How a Forced Air Convection Oven Works

A forced air oven utilizes an internal fan to circulate heated air throughout its chamber. This forced air movement ensures a consistent and uniform temperature distribution, which is a key advantage over gravity convection ovens that rely on the natural rising of hot air. The continuous circulation of hot air prevents the formation of cold spots, resulting in faster heating and drying times.

Common Applications

Forced air convection drying ovens are used in a variety of fields, including:

Laboratories and Pharmaceuticals: For drying glassware, sterilizing instruments, and preparing samples. They are crucial for maintaining sterility and ensuring compliance with standards.

Food Processing: Used for dehydrating fruits, vegetables, herbs, and meats to extend shelf life and preserve flavor and nutrients.

Chemical and Material Science: Used to dry powders, granules, and other moisture-sensitive compounds, as well as for curing resins and annealing metals.

Electronics: Used for drying and curing electronic components.

Key Features

These ovens typically have several key features that contribute to their effectiveness and safety:

Temperature Range: Most models operate from about 10-15°C above ambient temperature up to 250°C or 300°C, with some industrial models reaching even higher temperatures.

Digital Control: Advanced models feature digital PID controllers for superior temperature accuracy and programmable cycles.

Construction: The inner chamber is often made of stainless steel for corrosion resistance and easy cleaning, while the outer body is typically powder-coated steel.

Safety: Essential safety features include overheat protection and door interlocks to ensure safe operation.